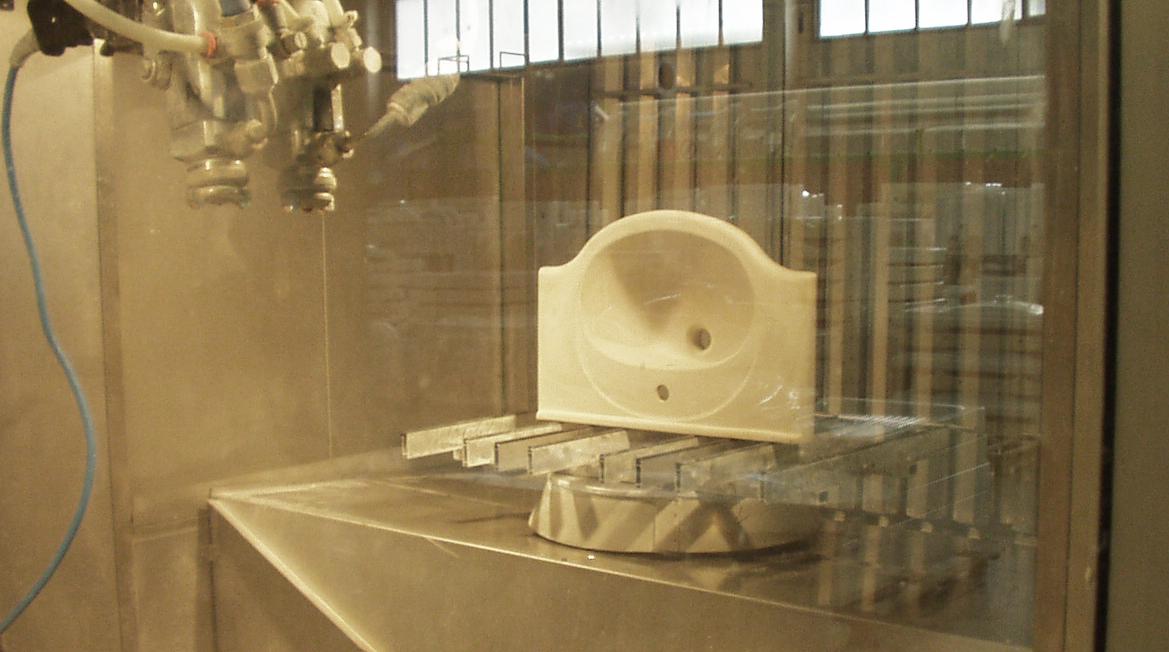

Off-Line programming software integrated with Glaze Dosing System

With the purpose of programming glazing robots, Whitech has developed a very sophisticated Off-Line programming software integrated with Glaze Dosing System (GDS) allowing the robotic system to easily program and efficiently execute complex glazing programs in the sanitary ware applications.

The Off-Line programming is composed by the following components:

•ROBO-GUIDE Off-Line software

•PAINT-Pro Application

•GDS – Glaze dosing system with mass flow control and Atomization and Fan air analog control.

ROBOGUIDE,

is a robot simulator program and houses a host of options for software products. The simulation occurs by using a virtual robot. Both the robot’s movement and application commands are simulated with this program. The software ensures a highly accurate simulation process when enlisting the help of ROBOGUIDE.

PAINT-Pro

Programming a robotic paint cell has never been easier.

Paint-PRO is entirely PC-based.

Programmers work off line, by using graphics to determine the specific paint path they wish the robotic arm to provide

•First, the size and position of the paint zone is selected.

•Second, the type of paint method is chosen.

•Third, the robot programmer goes through a number of steps to determine other criteria by selecting various parameters set forth by Paint-PRO.

•Once the robot programmer has finished, the program can be sent to the controller via Robotics Paint-Tool.

GDS (GIaze Dosing System)

GDS is dedicated to automatic control of glaze flow rate according to the value supplied to the gun and read by an instrument for measuring of mass flow.

The combination of these 3 modules represents a sophisticated tool for robot programming and glaze process optimization.