Whitech Glazing Systems

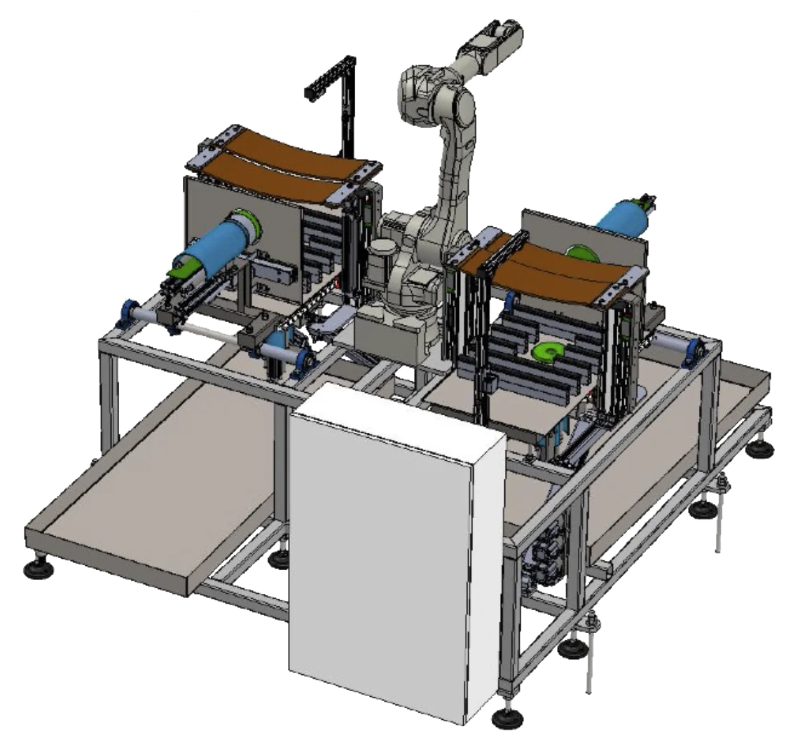

The robotized sanitaryware glazing system is an innovative modular system that combines flexibility and total automation.

The simplification of the mechanical components and the use of multifunctional robots make it possible to eliminate single-function mechanisms, making the line adaptable to different plant requirements..

Robotised enamelling: flexibility and total automation

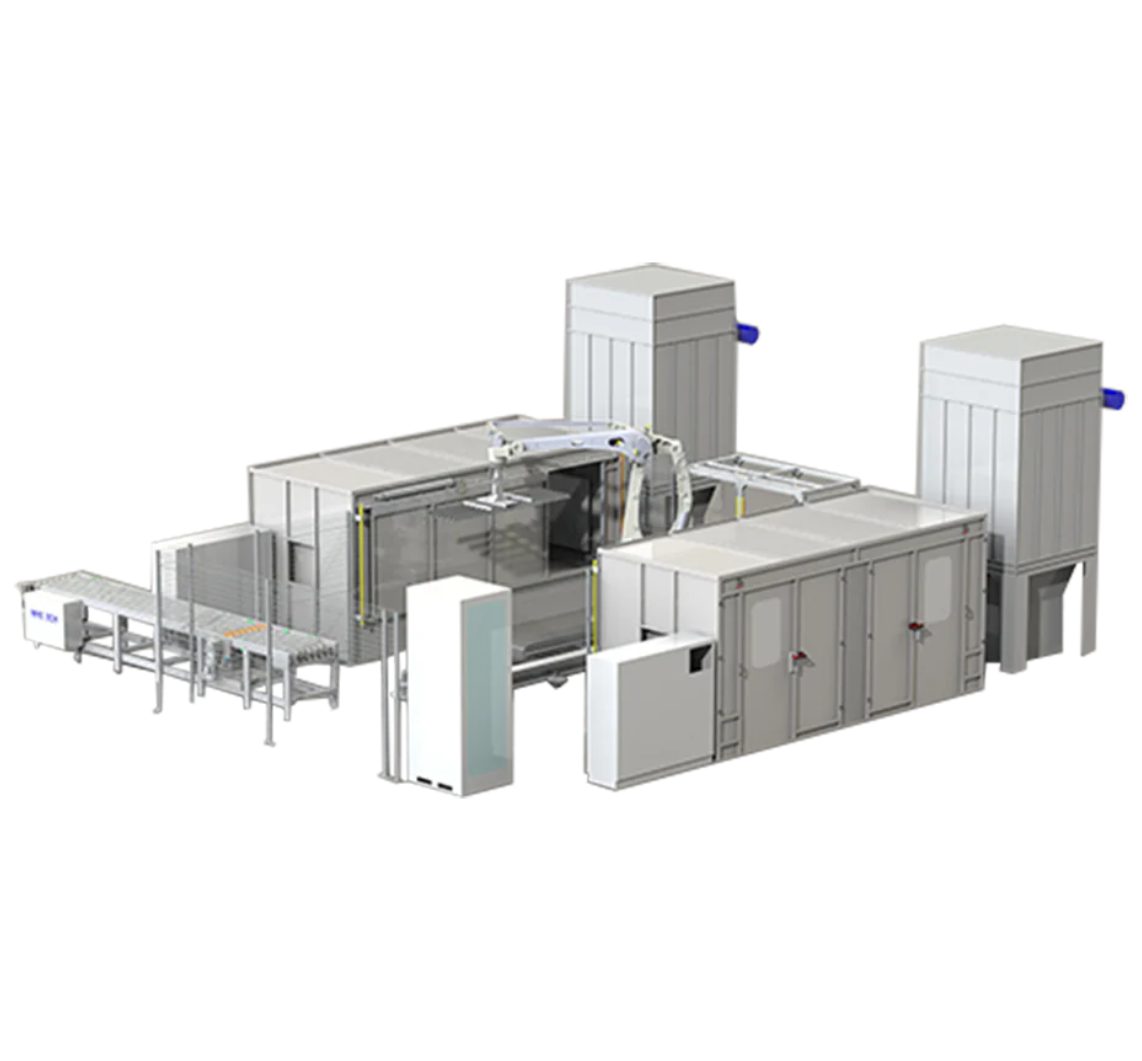

The WHITECH system represents a new standard in robotic sanitaryware glazing. Thanks to its modular structure, it adapts perfectly to different production requirements, guaranteeing maximum flexibility. The complete automation of the process is made possible by the elimination of single-function mechanisms and the use of multifunctional robots, which greatly simplify the line and increase its efficiency. The inspection phase, crucial for quality control, is supported by a stainless steel cabin, a camera centring device and a laser centring device, guaranteeing precision and safety. Handling robots with 4 or 6 axes, capable of handling heavy loads with precision, take care of the handling of parts within the line. The system is completed by an automatic siphon glazing station, integrated into the line, and the main glazing station, the heart of the process. Finally, a foot cleaning system removes excess glaze, while the inlet and outlet system, adaptable to both automated and manual lines, ensures an efficient workflow.

Learn more Close

OPERATOR SIDE

Stainless steel inspection booth with safety light beam Consisting of:

- Welded galvanised steel supporting structure

- Stainless steel panels to close both sides with flanges for connecting air ducts

- Stainless steel bottom panel

- Stainless steel upper panel

- Dust collection tray

- Light mounted in the centre of the upper panel

- No. 1 safety light beam protecting the operator during robot operations inside the cabin.

- No. 1 push-button panel with emergency button and button for activating the safety light beam

CAMERA CENTRING DEVICE WITH SUPPORT STRUCTURE

The workpiece centring system with camera assists the operator during the workpiece loading operation by providing information on correct positioning by means of a green light on the control panel.

The system consists of:

- Component support structure made of aluminium profiles.

- Camera

- Workpiece lighting system

- Control panel with HDMI screen

- Accessories and connection cables

LASER CENTRING DEVICE FOR INSPECTION BOOTH

Positioned above each station where products enter the enamelling area. The laser device enables correct centring of the workpieces to be enamelled. It fires two laser lines, which form a square angle set on the base, to be used as a reference point for positioning the workpieces.

Learn more Close

Infinite possibilities

At Whitech we have the ability and experience to install robots in our lines in different contexts. For this application, we choose robots with high loading capacity, large radius, speed and flexibility.

A model that meets the criteria of flexibility, speed, capacity, etc. adds to the high performance and loading capacity offered by these robot series.

Equipped with 4 or 6 axes for maximum flexibility, they can handle heavy loads with precision within a large working radius, making them the right choice for high load applications requiring excellent repeatability.

Learn more Close

Total automation in every detail

The robotic system for enamelling WC taps is a fully automatic device capable of performing the following functions:

- Siphoning the enamel by filling the piece with enamel from the drain hole

- Application of the enamel for WC taps by filling the complete piece with enamel

- Spray enamelling of the lower and front edge area

This device is generally installed within a robotised glazing line and is prepared in advance to be loaded and unloaded by the handling robot that connects the line components.

Learn more Close

Maximum flexibility + Total automation

The WHITECH system for robotized sanitaryware glazing represents a new plant concept which, thanks to the total modularity and integrability of the various components, allows maximum flexibility to be combined with total process automation.

The primary objective of the new concept is the simplification of the mechanical components, while respecting the automatic execution of all the operations involved in this process phase.

In particular, this objective has been achieved by acting simultaneously on two fronts:

- The elimination of all single-function mechanisms.

- The use of multi-function anthropomorphic robots that provide the highly efficient and flexible element for the integration of the various modules of the line.

The result is a line that is mechanically simple and adaptable to any type of plant requirement.

Learn more Close

A big time saver for the operator

After the enamelling cycle, when the robot has the workpiece on the fork, the most natural task it can perform is to clean the required part, removing excess enamel.

The complete system consists of:

- Painted steel frame

- Rotating sponge unit complete with gear motor, motor shaft and bearings

- Water collection tank with pump and cleaning nozzles

- Pneumatic workpiece lifting device

- Air and water systems with accessories

- Electrical cables and accessories

Learn more Close

Multiple choices by factory

The choice of input and output systems depends on the customer and the plant layout. Our selection of primary systems is suitable for both a fully automated line and manual handling by operators.

Our primary systems:

- Turret

- Conveyor

- Trolleys

Ceramic Division Catalog

Request the catalog