Whitech’s Ceramics Division

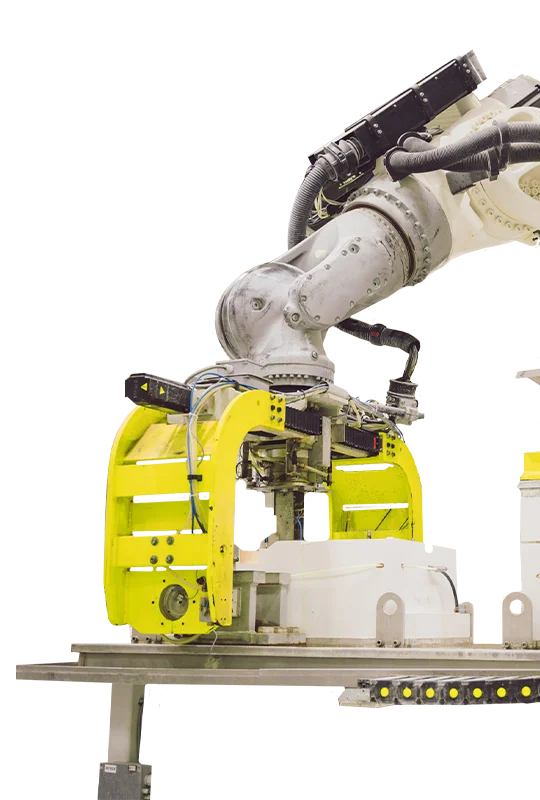

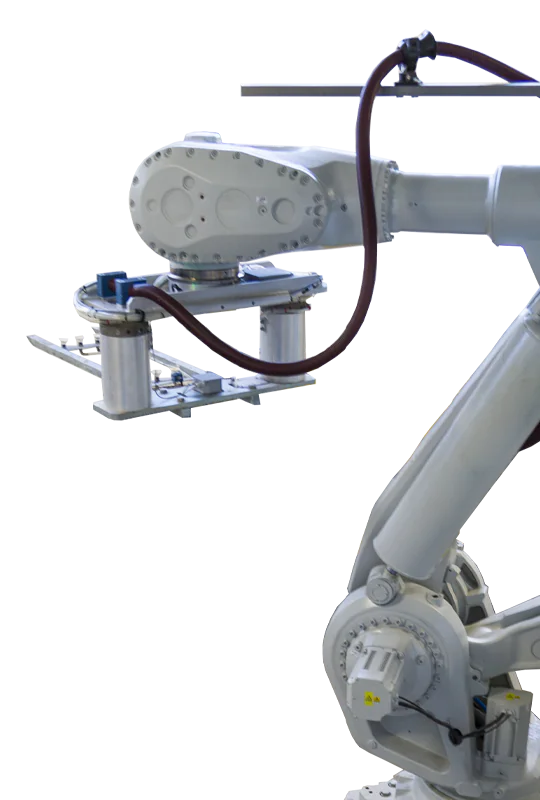

Whitech’s Ceramics Division is the historical heart of the company, specializing in the production of sanitary ceramics with complete and technologically advanced solutions. For years we have offered innovation and quality to optimize each stage of the production process, ensuring efficiency, precision and sustainability.

We create advanced solutions to revolutionize ceramic manufacturing.

Whitech is a cutting-edge company developing advanced technologies to optimize production efficiency, with an unwavering commitment to innovation and sustainability. We offer customized solutions and comprehensive consulting, guided by a passion for excellence and a professional approach.

Discover Whitech's strength through our numbers.

These figures reflect our ongoing commitment to excellence, innovation and customer satisfaction, testifying to our company’s growth and impact in the industry.

Innovative solutions for your ceramic production

Relying on Whitech’s Ceramics Division means choosing a partner with experience, innovation and a comprehensive offering. Discover why our advanced solutions can optimize your ceramic production, ensuring quality, efficiency and sustainability.