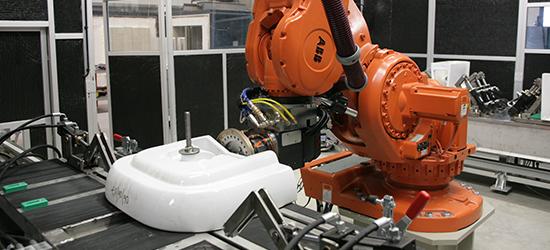

Robotic Grinding Cell

Multifunctional robotic grinding and cutting unit for any kind of sanitary ware pieces with double loading station.

No. 2 automatic sliding units for loading and unloading of pieces.

Each sliding unit is electrically operated and equipped with:

Loading frame for fixing of hydraulic unit for piece gripping

Hydraulic units for piece gripping

Hydraulic power plant

Device for the car blocking in the working position

Each sliding unit is completely autonomous so that it guarantees independent loading and offloading operations maximizing the productivity of the line. The piece gripping devices are designed depending on conformation of the piece and surfaces to be ground.

No. 1 Anthropomorphous 6-axis Robot equipped with:

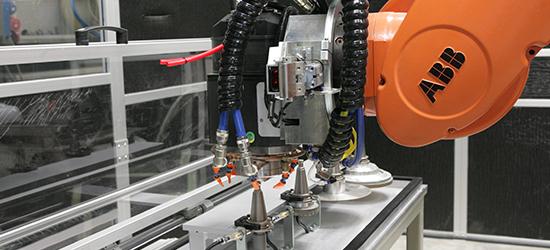

Electro-mandrel with tool change

Laser system for measuring of the surface to be machined

Grinding tool cooling system

Set of tools located in protected dispenser with automatic opening.

Laser system for measuring of consumption of grinding tools: this system allows automatic managing of consumption of the tool through automatic modification of the tool’s working point and substitution of used tool.

Sound-proof box

Containing the working area of robot with automatic doors in the area of two feed-in sliding units.

FULLY DEVELOPED PROCESS MANAGEMENT

The robot is equipped with laser measurement system which allows to verify the maximum planarity error of the surface to be worked.

This system can calculate:

the starting level for working of any surface

the number of rubs and the maximum depth of the single rub.

This measurement , combined with dynamic control of the velocity of movement of grinding tool, allows the robot to optimize working parameters, maximizing the quality of the finished piece and the productivity of the system.

With this specific control it is possible to define, depending of the code of the piece, the acceptable tolerance for every single working surface.

TOOL DISPENSER

The robot can be equipped with different tools for grinding, punching and cutting in order to adapt the system to any specific productive need.

The tools dispenser is equipped with laser sensor for automatic control of tools consumption which allows the robot to regulate the consumption through activation of “tool center point” in order to compensate the tool consumption guaranteeing the constant quality of the processed item.