Industrial automation can be described as a discipline or as a set of technologies and functions. Its advantages, characteristics and peculiarities are many and are largely dependent on the application sectors.

Automation, this term, indicates what is needed (tool, process or system) to ensure that one or more machines work automatically without direct human activity. Industrial automation includes all those technologies and systems capable of controlling and managing flows of materials, information and energy resources in one or more industrial production processes.

Industrial automation systems are divided into four types:

* Fixed automated systems

* Programmable automated systems

* Flexible automated systems

* Integrated automated systems

The origins and modern engineering

Industrial automation was born with the industrial revolution and received a great boost with the development of the American automotive industry. Since then it has experienced exponential growth, in terms of fields of application and technological performance.

Originally, the aim was to make the machine perform repetitive and alienating actions that were previously carried out by operators. This goal has remained, but has evolved, including expectations in terms of resource optimization and speed of execution.

In fact, history speaks for itself: in particular in the last two decades, automation has enabled many companies and organizations to improve the processes of control and production of goods and services, significantly reducing execution times, errors and outsourcing.

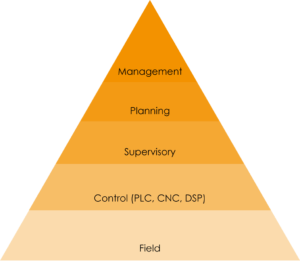

The CIM pyramid, Computer Integrated Manufactory

To understand and visualize the logic of an automated system at an industrial level, it is possible to use the CIM pyramid.

At the base of the pyramid is the field to be controlled where all the sensors connected to the processes and which are intended for data measurement are placed. These data reveal the progress and the correctness or otherwise of the execution of the process.

At a higher level of the pyramid are the control devices and actuators. These are tools that process the data acquired by the sensors and combine them with the parameters of the objectives desired by the automated process, and then implement direct actions on the system.

The last two steps of the pyramid are that of supervision via computer and remote monitoring tools, to conclude with company activities.

It is a scheme, here extremely simplified, very effective for understanding how an automated system has a direct, but progressive, impact in every area of the company: production, management and decision-making. It is therefore evident that an automated system is able to function at its maximum potential when it is designed on the basis of specific needs, unique to each individual company.

Every company that chooses to automate one or more processes, if not even an entire production line, looks for solutions designed on its specific needs and objectives, among which the most widespread is undoubtedly the reduction of costs and processing times. greater productivity and less risk for the operator.

Customization and system integrators

Making all these needs converge in a high-performance automated solution is above all the task of a system integrator, capable of thoroughly analyzing a pre-existing condition, finding its criticalities and exploiting the characteristics of automation to bring about a positive change in the specific process.

In the past, industrial automation intimidated many companies. Today the perception has changed. The opportunities offered by an automated solution, from the robot to the simple press, are more within everyone’s reach and not the exclusive prerogative of companies capable of making very large investments. Today, a robotic island, for example, has an average payback of less than one year.

In particular, at Whitech we put at the center of our studies, designs and productions, the maximisation of the efficiency and productivity of our customer with customized and usable systems.

The automated process was created to reduce human intervention in certain production phases, particularly alienating or dangerous, today the human component does not disappear, but is qualified with active control, monitoring and maintenance tasks.

The ease of use for the final consumer, who in the case of industrial automation are supervising or specialized operators, is therefore of primary importance to ensure that process automation becomes increasingly widespread and within the reach of as many companies as possible.

To go into the details of your reality, let’s get in touch today!